Generic drugs are the backbone of affordable healthcare - and they’re changing faster than ever

By 2030, nearly one in two prescriptions worldwide will be filled with a generic drug. That’s not just a number - it’s a lifeline for millions who can’t afford brand-name medicines. The global generic drug market, worth $435 billion in 2023, is on track to hit $690 billion by 2034. But this isn’t a simple story of more pills at lower prices. The future of generics is being reshaped by complex supply chains, rising biosimilars, regulatory battles, and geopolitical shifts that few see coming.

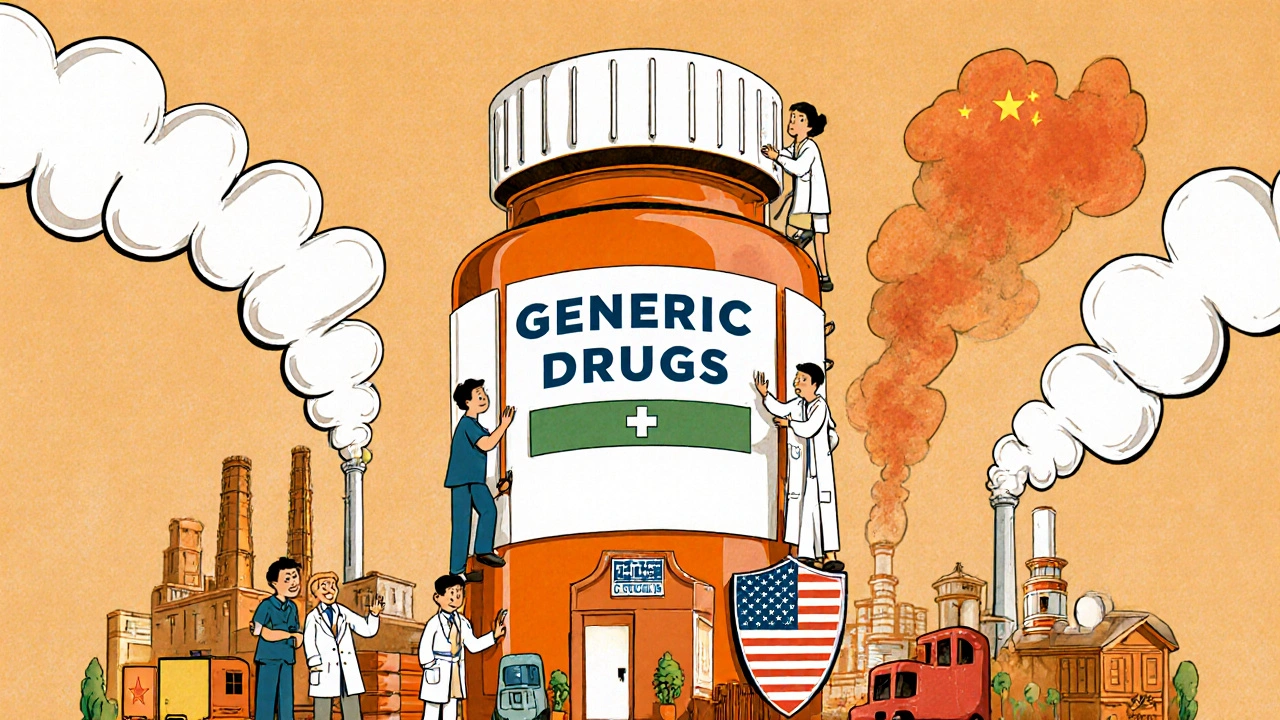

What’s really happening? It’s not just about cheaper pills anymore. It’s about who makes them, where they come from, and whether they’re safe. In the U.S., generics make up 90% of prescriptions but only 23% of drug spending. In India, over 60,000 generic medicines are produced every year. China supplies nearly two-thirds of the world’s active pharmaceutical ingredients (APIs). These aren’t abstract stats - they’re the real wires powering global health.

Why generics are more critical than ever

Healthcare costs hit $9.8 trillion in 2024. Chronic diseases like diabetes, heart disease, and cancer affect 41% of the global population. Governments are stretched thin. Insurance systems are under pressure. In this environment, generics aren’t optional - they’re essential.

Take blood pressure meds. A branded version might cost $150 a month. The generic? $15. That’s an 80-85% drop. Same active ingredient. Same effectiveness. Same FDA or EMA approval. But the savings? Life-changing for families, clinics, and public health budgets.

Without generics, millions would skip doses or go without treatment. In low-income countries, where out-of-pocket spending is high, generics are often the only option. Even in wealthy nations like Germany and Canada, generic use is mandatory in public drug programs. The math is simple: more generics = less financial strain on health systems.

The rise of biosimilars - the new frontier

For years, generics meant small-molecule drugs: pills you swallow, like metformin or lisinopril. But now, the fastest-growing segment isn’t those. It’s biosimilars - copies of complex biologic drugs like Humira, Enbrel, or Keytruda.

Biologics are made from living cells. They’re huge, intricate molecules. That’s why making a copy isn’t like copying a CD. It’s more like cloning a human heart. Biosimilar development takes 10-20 times more steps than a traditional generic. Costs? $100-250 million. Compare that to $1-5 million for a standard generic.

But the payoff is huge. Biosimilars are priced 15-30% below the original biologic - not 80% like traditional generics. Why? Because manufacturing is harder, and regulators demand more data. Still, that’s enough to save health systems billions. By 2030, biosimilars are expected to grow at 12.3% annually, outpacing all other generic segments.

Companies that stuck to simple pills are now racing to build biosimilar labs. Some failed. Others are partnering with biotech firms. The ones that don’t adapt won’t survive.

Who’s driving the market? Asia leads, but the story is more complex

India and China together control about 35% of global generic manufacturing. India alone produces 20% of the world’s generic drug volume by quantity. China makes 40% of all active pharmaceutical ingredients (APIs) - the building blocks of every pill.

But here’s the catch: this isn’t just about volume. It’s about control. China supplies 65% of APIs for generics globally. That’s a vulnerability. If a factory in Shanghai shuts down due to regulations, environmental issues, or political tension, drug shortages ripple across the U.S., Europe, and Africa.

That’s why countries are pushing back. The U.S. and EU are funding domestic API production. India’s PLI scheme gave $1.34 billion in 2024 to boost local manufacturing. Egypt now requires 50% of essential medicines to be made locally by 2025. Saudi Arabia’s Vision 2030 is investing billions in pharmaceutical infrastructure.

It’s not about nationalism. It’s about resilience.

Regulatory chaos - 78 different rules, one global market

There are 78 different regulatory systems for generic drugs worldwide. The FDA in the U.S. has one set of rules. The EMA in Europe has another. Brazil, Nigeria, Indonesia - each has its own standards.

This creates chaos. A pill approved in India might be rejected in Canada because of a different impurity limit. In 2023, the FDA issued 187 warning letters to foreign generic manufacturers - 40% of all warning letters that year. Most cited poor quality control, unclean facilities, or falsified data.

Some countries are trying to fix this. The International Council for Harmonisation (ICH) added 15 new members in 2024. More countries are adopting common testing standards. But progress is slow. Smaller generic makers - especially in Africa and Latin America - still struggle to meet global standards. That means some medicines on shelves aren’t just cheap - they’re risky.

Profit margins are shrinking - and so are the players

Generic drugmakers used to make 18% profit margins in 2020. Now? It’s down to 12%. Why? Too many competitors. Too many products. Too little pricing power.

In the U.S., when a drug’s patent expires, 20-30 companies jump in. Prices crash overnight. A 10mg tablet of atorvastatin (Lipitor’s generic) now costs less than $0.05 per pill. Manufacturers can’t make money on that. So they exit. Or they consolidate.

Big players are buying up small ones. Companies like Teva, Sandoz, and Sun Pharma are growing through acquisitions. Smaller firms either get swallowed or pivot - to biosimilars, complex injectables, or niche markets like orphan drugs.

Those who survive are the ones who stop playing the price game. They’re building service models: supply chain management, inventory tracking, even direct-to-clinic delivery. They’re becoming logistics partners, not just pill suppliers.

The pharmerging markets - the real growth engine

North America and Western Europe? Growth is flat - 2-5% annually. Why? Price controls. Government negotiations. Strict formulary lists.

But in places like India, Brazil, Turkey, and Saudi Arabia? Growth is hitting 9-10% a year. Why? Rising incomes. New insurance programs. Expanding clinics. Governments are actively pushing generics to cut costs.

India’s National Pharmaceutical Pricing Authority caps prices on 348 essential medicines. China’s Healthy China 2030 plan prioritizes generic access. In Nigeria, the government now pays for generics through national health insurance. These aren’t pilot programs. They’re national strategies.

By 2025, these emerging markets will add $140 billion in new drug spending. Most of it will go to generics. That’s where the future is being built - not in Wall Street boardrooms, but in clinics in Lagos, Dhaka, and Bogotá.

The big threat: supply chain fragility

Think about your phone. Now imagine it’s made of parts from five different countries. One factory stops making a chip. Your phone dies.

That’s the generic drug supply chain. APIs come from China. Packaging comes from India. Final assembly happens in Mexico. Distribution flows through Singapore. One breakdown anywhere - a fire, a flood, a trade ban - and hospitals run out.

After the pandemic, every country realized this. The U.S. passed laws to fund domestic API production. The EU launched the Pharmaceutical Strategy to reduce dependency. But it takes years to build a new API plant. And the money? It’s still not enough.

For now, the world still relies on a few key hubs. If China ever restricts API exports - for political, environmental, or economic reasons - the ripple effect could be global. And no one has a backup plan.

What’s next? Three clear trends

- Biosimilars will dominate growth - Traditional generics are a mature market. Biosimilars are the new gold. Companies investing now will lead in 2030.

- Local production will rise - Countries won’t risk shortages again. Expect more factories in Latin America, Africa, and Southeast Asia - even if they’re smaller.

- Quality will trump price - Buyers are tired of unsafe generics. Regulators are cracking down. The cheapest pill won’t win anymore. The safest one will.

The era of the low-cost, low-quality generic is ending. The future belongs to manufacturers who combine affordability with reliability. Those who can deliver consistent quality across borders will be the winners.

Will generics still matter in 2030?

Yes - but differently.

By 2030, generics will still make up over half of all prescriptions. But their share of total drug spending will drop from 57% to 53%. Why? Because specialty drugs - like GLP-1 weight-loss meds and gene therapies - are exploding in price and use.

Generics won’t be the biggest revenue driver anymore. But they’ll still be the most important. Because while a $1,000-a-month injection might make headlines, it’s the $5 generic insulin that keeps people alive.

The future of global generics isn’t about being the biggest. It’s about being the most reliable, the most accessible, and the most trusted. That’s not just a market trend. It’s a moral imperative.

Are generic drugs as safe as brand-name drugs?

Yes - if they’re made to regulatory standards. Generic drugs must contain the same active ingredient, strength, dosage form, and route of administration as the brand-name version. They’re tested for bioequivalence - meaning they work the same way in the body. The FDA and EMA require the same quality controls. But quality varies by manufacturer. Drugs made in facilities with warning letters or poor inspection scores may not be reliable. Always check the manufacturer and regulator approval status.

Why are some generic drugs cheaper than others?

It’s about competition and production cost. When a patent expires, dozens of companies may start making the same drug. The first few get higher prices. As more enter, prices drop. Drugs made in countries with lower labor and regulatory costs - like India or China - are usually cheaper. But cheaper doesn’t always mean better. Some low-cost generics come from facilities with poor quality controls. Always look for approval from trusted regulators like the FDA, EMA, or WHO.

What’s the difference between a generic and a biosimilar?

Generics are copies of small-molecule drugs - simple chemical compounds like aspirin or metformin. Biosimilars are copies of large, complex biologic drugs made from living cells - like insulin or cancer treatments. Biosimilars can’t be exact copies because living cells vary slightly. They’re highly similar, but not identical. That’s why biosimilars cost more to develop ($100-250 million vs. $1-5 million) and are priced higher (15-30% below brand) than traditional generics (80-85% below brand).

Which countries produce the most generic drugs?

India and China are the top two producers. India manufactures over 60,000 generic medicines and supplies 20% of the world’s generic drug volume by quantity. China produces about 40% of global active pharmaceutical ingredients (APIs) - the raw materials for pills. Together, they control roughly 35% of global manufacturing capacity. Other major producers include the U.S., Germany, and South Korea - but they focus more on high-value generics and biosimilars.

Are generic drugs regulated the same everywhere?

No. The U.S. FDA and European EMA have strict standards. But in some countries, especially in Africa and parts of Asia, regulatory oversight is weaker. A drug approved in India might not meet U.S. or EU standards. That’s why some generic drugs are flagged for safety issues. Always check if the manufacturer is approved by a recognized authority. WHO prequalification is a good indicator of quality for international use.

Is the global generic drug supply chain at risk?

Yes. Over 65% of active pharmaceutical ingredients (APIs) come from China. If supply is disrupted - by trade policy, natural disaster, or political conflict - shortages can happen fast. The U.S. and EU are trying to reduce this dependency by funding local production, but it takes years to build new facilities. Until then, the system remains fragile. Countries are now investing in regional manufacturing hubs to reduce risk, but global reliance on China won’t disappear overnight.

Matthew Karrs

November 21, 2025 AT 01:04Gerald Cheruiyot

November 22, 2025 AT 17:52Michael Fessler

November 22, 2025 AT 23:25daniel lopez

November 24, 2025 AT 12:37Destiny Annamaria

November 24, 2025 AT 17:34Alyssa Torres

November 26, 2025 AT 07:52Summer Joy

November 26, 2025 AT 15:22Aruna Urban Planner

November 28, 2025 AT 04:12Nicole Ziegler

November 28, 2025 AT 04:40Bharat Alasandi

November 28, 2025 AT 23:11Kristi Bennardo

November 30, 2025 AT 23:00Shiv Karan Singh

December 2, 2025 AT 18:16Ravi boy

December 3, 2025 AT 18:19Matthew Peters

December 5, 2025 AT 15:08